Produkt beskrivelse

2 / 3 - components polyurethane form in plance foam gasket, FIPFG, automatic PU foam gasket making machine & equipment

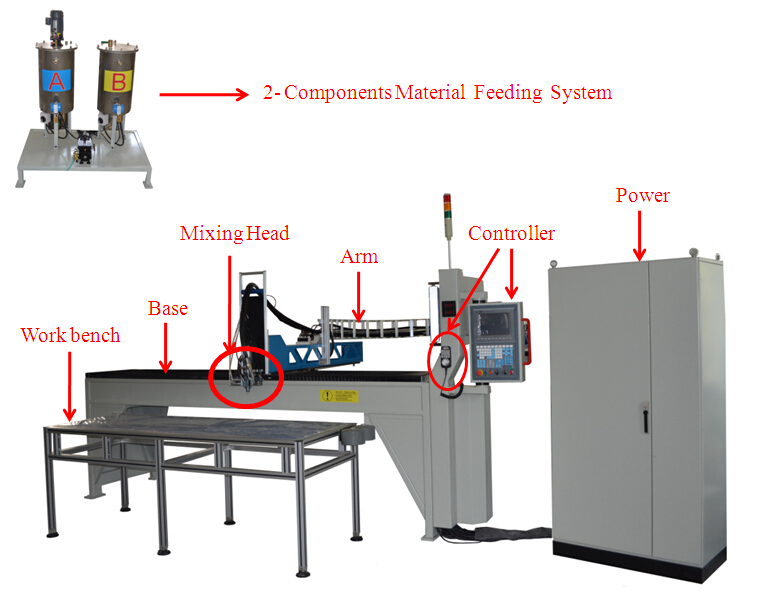

This machine can mix two (or three) kinds of raw material together and pour to pre-set position, groove, mould, or the flat surface of workpiece directly. Through chemical reaction, the liquid raw materials form elastic sealing strip in seconds. There is no joint or cut point, so comparing with other kind of sealing its effect is much better and with longer using life. And, during the forming process, the sealing strip surface become very smooth and without any crack, so its sealing effect is perfect. And, because it can stick on the workpiece naturally and tightly, no gluing worker is needed, huge cost is saved from labor and time, etc.

Skumforseglingsudstyr anvendes mere og mere i tætningsfelter som kontrolskabe, belysning, motorkøretøj, maskinindustri mv. Det er lækagesikker, oliesikker, vandtæt, dæmpning, støjsikker og tætning mv. Det er i overensstemmelse med certificeringer som UL / CE, MIL-STD-167, EN50298 og så videre.

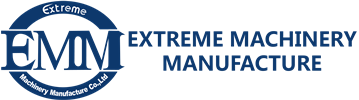

Foam Gasket Manufacturing Machine Equipment Construction:

Gasket Manufacturing Machine Standard type equipment specifications:

| Tekniske specifikationer | Nogle andre detaljer | |||

| Mekanisk arm | 6 * 3 m | Teknologi | Fra Tyskland | |

| Workbench | 2,4 * 0,9 m | Mixing Head | Fra Tyskland | |

| Materialebænk | 1,2 * 0,85 m | Operation | Fra Taiwan Syntec, CNC system | |

| Arbejdsstreg | 2,4 * 1,2 * 0,25 m | Håndkontrol | Fra Taiwan Syntec | |

| Strip Width | 3.5-30 mm | Motor | Panasonic Servo Motor | |

| Limning Præcision | 0,01 mm | Målepumpe | Fra Tyskland, Barmag | |

| Arbejdshastighed | 0-12 m / min | Rengøring | Vandrisiko | |

| Højeste hastighed | 30 m / min | Materiale Tønder | Dobbeltvægget rustfrit stål, kontrol temperatur automatisk | |

| Gentag positioneringsnøjagtighed | +/- 0,03 mm | Kontroltilstand | 8 akselkobling, 1X + 1Y + 1Z + 1mixing + 2metering + 2reserving | |

| dosering | 0,5-5 g / s | Arbejdsmodus | 2D eller 3D | |

| Fyldningsnøjagtighed | 0,1 g / s | Hovedfarve | Sølvgrå, se billede, eller sort, rød, ect. under diskussion. | |

| Blandingshastighed | 0-3000 rad / min | Custom-made, OEM, ODM | Ok intet problem. | |

| Blandingsforhold | 1: 10 ~ 10: 1 Justerbar | Certificeringer | CE, RoHS, ISO osv. | |

Foam Gasket Manufacturing Machine Main Parts

1. Blandingshoved:

Water Rinsing & Modular Design, or recycled chemical solvents for arid zone countries.

2- / 3- komponent blandingshoved med højtryksvandsspolningssystem og dynamisk blandesystem til brug med væske til højviskøse polymerreaktionsmaterialer til pakning, limning og potting.

2. Driftssystem:

CNC-system fra SYNTEC, 180 grader roterende frit, Multi-sprog valg, Opbevaring af stor ofte brugt information, Plus USB-grænseflade og G-kode program. Manuel betjening kan også vælges. Kan betjenes simpelthen.

3. Råmateriale tønder:

Dobbeltvægget rustfrit stål, kontrol temperatur automatisk.

4. Arbejdsbænk:

Aluminiumslegering, stærk og holdbar.

5. Doseringssystem:

Barmag metering pump, Panasonic servo motor, Microscale (2-8mm) gluing is workable.

6. Håndkontrol:

SYNTEC lavet, let styring, respons hurtig og stabil.

7. Kørselssystem:

Panasonic servo motor, work steady, long using life.

| ** Advantages of Jinjie's Gasket Manufacturing Machine ** | |||

| Vores firma, Jinjie | Nogle andre virksomheder | ||

| Teknologi | Fra tysk, øverste niveau, modent og stabilt | F & U i Kina, kinesisk niveau, researching problems happened during the machines' using progress, then find out reasons and develop new types | |

| Mixing Head | German technology and quality, Special Teflon coating for prevent residual |  | Kinesisk kvalitet. (the shape and structure keep changing, two or three years later, the old type will disapear; then, maintenance and after-sales service will become very difficult. |

| Arbejdsmodus | 2D eller 3D til valg (kunne behandle specielle 3D-mønstre) |  | Kun 2D |

| Kontroltilstand | 8 akselkobling som helhed (1X+1Y+1Z+1Mixing +2Metering+2Reserved, Could adjust & change to 3-components equipment or adding auto material feeding system according to needed.) | 3 akser + andre styresystemer, the stability is not good enough. | |

| Strip Width (Standard type) | 3.5-30mm | 8-30mm | |

| Strip Width (Mikro-type) | 2-8mm | 3-8mm | |

| Gentag positioneringsnøjagtighed | +/- 0,03 mm | +/- 0,05 mm | |

| dosering | 0,5 ~ 5 g / s | 1 ~ 4g / s | |

| kontinuerlig Arbejdstid | kan fortsætte med at arbejde for en hel dag (der er en speciel belægning på blandehovedet for at forhindre rester) | Ofte stopper midlertidigt for cleaning residual, otherwise the mixing head will be clocked | |

| After-sales Service | Jinjie's professional after-sales service group, technicians are English speaking (the machine itself has very low failure rate, the maintenance is very simple and quick) | High failure rate, complex maintenance progress; after-sales service outsourcing, professional degree is limited, cost is very high. | |

| Behandlingsevne af fabrikken | machine shop belongs to ourselves, Jinjie; the metal frame is manufactured, assembled and adjusted by ourselves, high precision, good stability | The metal farme is manufactured by another one or more companies, then assembled together directly without testing, the stability is not good enough. | |

| Quality & Offer | Top level German quality, Price is very competitive | Common standard quality, price is not competitive | |

Ansøgninger:

EMM FIPFG Sealing Equipments are widely used in fields like cabinets, vehicle, electronic, appliances, lighting, and filter, etc.

Power cabinets: Gluing and sealing on the surfaces of controller cabinets, power boxes, enclosures, doors, or other surfaces or groove, to prevent dust and moisture.

Belysning: Gennem skummende tætning til dannelse af tætningsringe på belysninger til industri, møbler, hus eller udendørs mv.

Små beholdere & pakkekasse: tætningsringe brugt på dækkanten af dem med en masse mængder for at afslutte forseglingsprocessen effektivt og automatisk.

Appliances: sealing strips are needed for kitchenware’s top, back and inside, or filter of cleaner, and other appliances.

Køretøj: Tætningslister, der bruges på bilens karrosseri, pedal, ratstativ, brandsikker metalplade og andre områder som bilrude, udluftning, belysningsdæksel, klimaanlæg og så videre.

Filter: like those used on oil industry, air conditioner, building, refrigerator, etc

Hurtige detaljer

Forarbejdningstype: Skummemaskine

Tilstand: Ny

Product Type: foam sealing gasket

Oprindelsessted: Kina (fastlandet)

Brandnavn: EMM

Spænding: 380V

Power(W): 4500W

Dimension(L*W*H): 6*3*2m

Vægt: 1000 kg

Certificering: CE

Garanti: 1 år

Eftersalgsservice Forudsat: Ingeniører til rådighed for service i udlandet

Type: FIPFG form in place foam gasket

Strip width: Micro type: 2-8mm; Standard type: 3.5-30mm

Teknologi: Blandingshoved designet og fremstillet i Tyskland

Doseringssystem: Barmag doseringspumpe

Kontrolsystem: Taiwan Syntec CNC system med håndregulator

Kørselssystem: Panasonic servomotor

Cleaning system:Water rinsing (or chemical solvent for arid zone countries)

Working speed: 0-12m/s, usually be 6-10m/s; moving speed could be 30m/s

Råmateriale: Polyuretan, PU, Silikone, andet flydende materiale

Certifications: CE, ISO, RoHS, SGS, CQC, etc